|

Model |

FD10-250c |

FD10-320c |

FD10-400c |

|

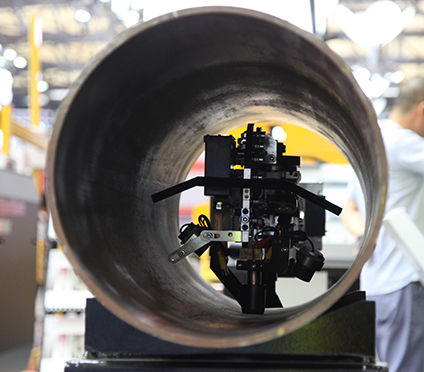

Min. internal diameter (mm) |

Φ250 |

Φ320 |

Φ400 |

|

Length of workpiece (mm) |

≤2000 |

≤3000 |

≤4000 |

|

Movement stroke of slide¥≤±∏ (V×H) / mm |

25×25 |

30×60 |

50×100 |

|

Wire diameter (mm) |

Φ1.2~Φ1.6 |

Φ2.4~Φ3.0 |

Φ3.0~Φ4.0 |

|

Wire strengthen accuracy (mm) |

≤±1 (Extend 20 mm) |

≤±1 (Extend 30 mm) |

≤±1 (Extend 40 mm) |

|

Seam type |

Longitudinal |

Longitudinal circumferential |

Longitudinal circumferential |

|

Rated welding current (A) |

630 |

1000 |

1000 |

|

Duty cycle |

100% |

||