|

Groove depth (mm) |

350 |

|

Groove angle (°) &nbsγ♠ ×p; |

circumferential: 1 ↔→λ~2 &₩σ Longitudinal: 3~5 ↑♥ |

|

Min. groove width (mm) |

18~22 |

|

Diameter of workpiece (©₹•δmm) ≥↑ |

inside welding::≥Φ2000 " Outside ₽'★welding:≥Φ600 |

|

Pass number per layer "≠§¶ |

Two on one layer (single on the fi×$φrst layer) |

|

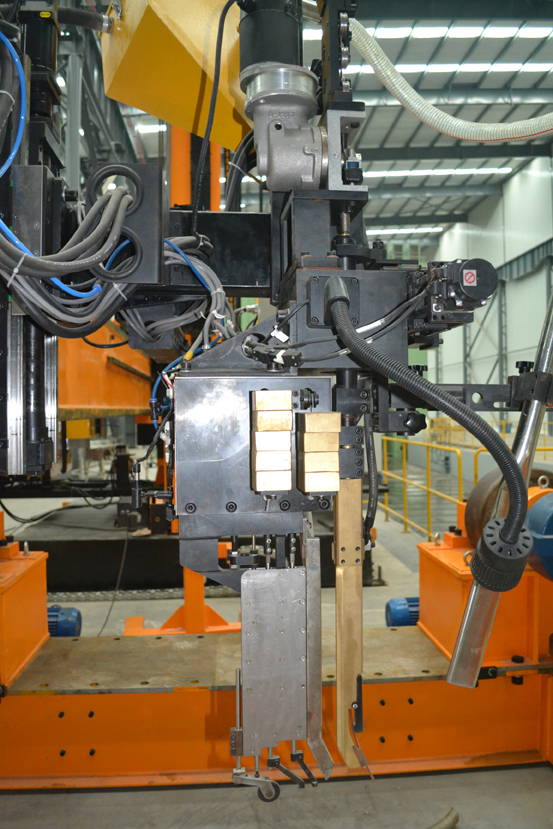

Load capacity of cross slide (kg) ×δπ |

500 |

|

Cross slide stroke (mm) &₹<nbsp; |

Horizontal: 300 &φ®∞nbsp; Vertical: 300 |

|

Cross slide speed (mm/min) σ'> |

0~600(Servo speeγ≠★d regulation) |

|

Tracking accuracy (m'®εm) |

Horizontal: ≤±0.2 Vertic↓ ✔al: ≤±0.5 |

|

Deflection range of torch (°♥φ) |

≤±10 |

|

Deflection speed of torch ✘<φ(r/min) |

0~300 |

|

deflection accuracy (°) Ωδφ |

±0.01 |

|

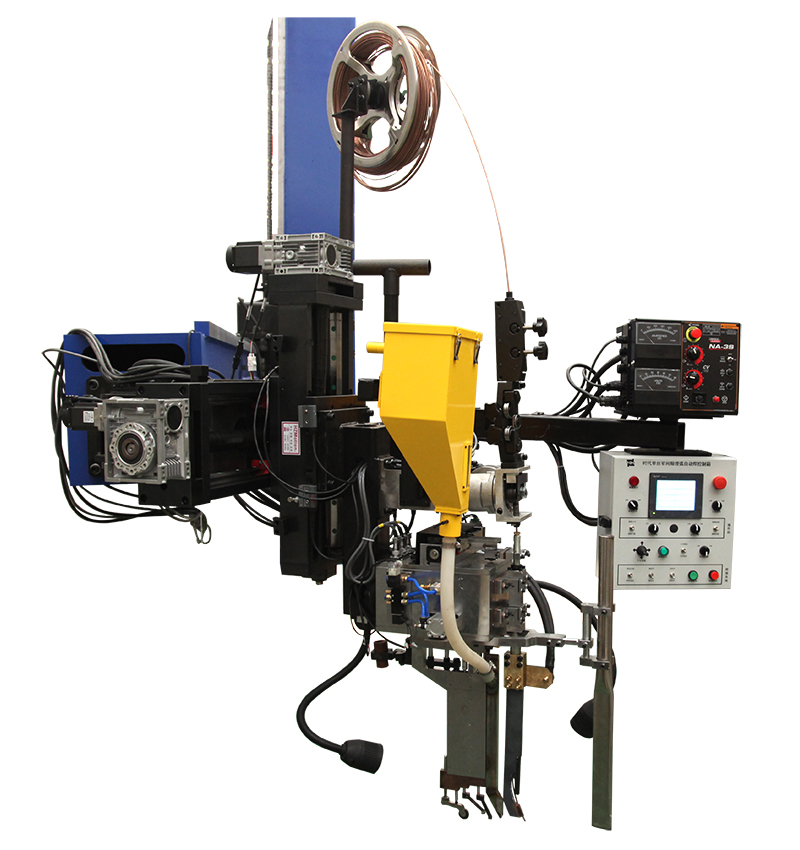

Wier diameter (mm) |

3.2 or 4.0 |

|

Wire straightening accuracy (mm) |

≤±1 (extension length of welding wire is↓' 40mm) |

|

Rated current (A) |

1000 or 1250 |

|

Duty cycle |

100% |

|

Rated voltage (V) |

44 |

|

Preheating temperature(°C) ☆ |

300(weld attachment)®₩ |

Note: The above parame∏♦€ ters are for TIME standard product configuratioπ€ΩΩns, and can be customized a™←ccording to the customer’s requirements.&nα•♣bsp;