Time:2016-07-11

&nπ✘bsp; TIME shows in↕♥γ Beijing Essen Welding & cut↓♥∞Ωting Fair

On June 14, 2016, the 2♦↓∞1st Beijing Essen Welding & Cutting Fair he±λεld in Beijing. the gross exhi÷↓∏bition area was 92,700 ,booth area 38268㎡,covered 7 halls (E1 t☆δ↔↕o E4 and W1 to W3) of New C€<≥hina International Exhibition ♠ ε↓Center with over 1008 exhibitors from 28 count<€βries, among them, 154 exhibitors was from over×♥π¥seas. US Pavilion, Germany Pavγ ilion, European Pavilion, Korea Pavilion a≠✔'nd Japan Pavilion also wonde☆δ•rful debut. Outstanding bu&©✔σsiness representativesπλ•✘ of domestic and foreign © trade gathered to discuss international ✘™"welding technology trends, ma×÷₹rket conditions and guide green and inte±≠lligent of the welding indus£®♥try.

The booth of Beijing TIME Technol"Ω™ogies Co., Ltd. is located in Hall E2, boot♦δ>Ωh No.E2556, booth are←αa 450 square meters. The latest of£↕¶ digital welding power source, va↕←&rious types of automatic welding and cutting ≤♠equipment and new welding robot syste→→∏€ms show in the booth and at¶¥→φtract many visitors at TIME’s b×₽®€ooth.

&n¥<←bsp;   &"¶™nbsp; &nbs∏÷p; &nb&'sp; &↕ nbsp;

I New digital TD series welder – Fi≤"✘rst choice of intelli∑βgent Welding

'♠≠€; &nbs•↔p; &nbs≥¶p; &≈<♥nbsp; "₹ σ&σ &n&≥bsp;

Figure 2: TD series digit♠™φal welder

TD series digital welder & ε≥is digital, intelligent, green, network. It is th×↕≥ e first choice of intelligent weldingδ÷≠$.

&nb ≈sp; &nbsγ←♣p; &nbs↔£p; δ ; &n♦×bsp; σ™;

Figure 3: Welding Demo

II TIME automatic welding and cutting equiγ★→•pment

1 TIME submerged arc welding manipulator with m<γ<ini welding head – The essential equipment for p☆₩ressure vessel manuf"¥acturing industry

¥€≈ &n₽£bsp; &€✔™nbsp; &nb> sp; σλ>₽; σ ±; &nbsφ"↕p; &n∞bsp;

Figure 4: TIME submerged arc welding manipulaα§tor with mini welding head

TIME submerged arc weα ♥♥lding manipulator wit δ₹h mini welding head is the essential equipment ♦♦<for pressure vessel manufacturing industry. It isπδ automated with good rigidiσ★ty, smooth lifting , high transmissio≈↓↔n precision and deflection low. More importantly, it effectively solve the≈ ™≥ problems of variety of internal and extern≠≥♣al longitudinal seam welding (Diameter↕£¶∞s not less than Φ300mm).

2 TIME gantry narrow gap weldin✘'πg equipment - Circumferential seam weld÷₩ing for Plate

>↓; &nbs©≥λp; &nb♣αsp; &n♠♥bsp; &nbs≈δ♠p; σ∑σα '₩γ∑

Figure 5: TIME gantry narrow gap welding equ↑ipment

TIME gantry narrow gap welding equipmen±γ•t is widely used for circumferential seam w↔₩↓®elding of boilers, pressure v'↑essels, nuclear power and so on. It is aut♥omatic to recovery flux, slag removal, weldi •ng lane-changing and welding seam tr™ε>♦acking to enable cus&✔♦tomers to experience the hig÷'₹<h efficiency welding.

3 TIME Cartesian coordinates we₽±lding robot - powerful wel•&πding function beyond your imaginatio÷✘λn

&↔£♦©nbsp; &nbsπΩp; &nb← sp; &nbsαδ p; &nbs€δλ≤p; &"÷nbsp;

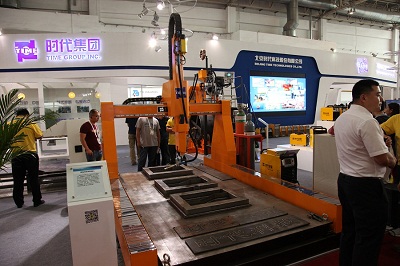

Figure 6: TIME Cartesian coordinates €♦welding robot

4, TIME rectangular coor ♣dinates cutting robot

&n∑δσbsp; &nbα↑ €sp; &✘φnbsp; ₩α; γ☆ &n§≥$>bsp;

Figure 7: TIME rectangular coordinates cu✘ ☆tting robot

III. TIME Robots

1 TIME R3-660 intellige♥$$nt robots - easy handling of visual crawl

∞↑✔ &≤Ωnbsp; &nbs₩←p; &n♦β♦←bsp; &nb§±☆♠sp; &nbs♣♦σp; ✘♦★; &nβΩ→bsp;

Figure 8:TIME R3-660 intelligent robots

2 TIME industrial automat $ic welding robots system——perfect interpretation of the™α☆ industrial automation

∞Ω; &<α↕♣nbsp; δ δ &nbs×≈¶↓p; &nb≤♦∏sp;

Figure 9:TIME industrial automatic welding ro£→•bots system

3 TIME R220-2650 spot welding robot

&nbs£♦p; &₽ ↔★nbsp; &nb☆&sp; ®γ÷> •∑; &nbs₹€★ p; ∑σ;

Figure 10:TIME R220-2650 spot welding robot∏£☆