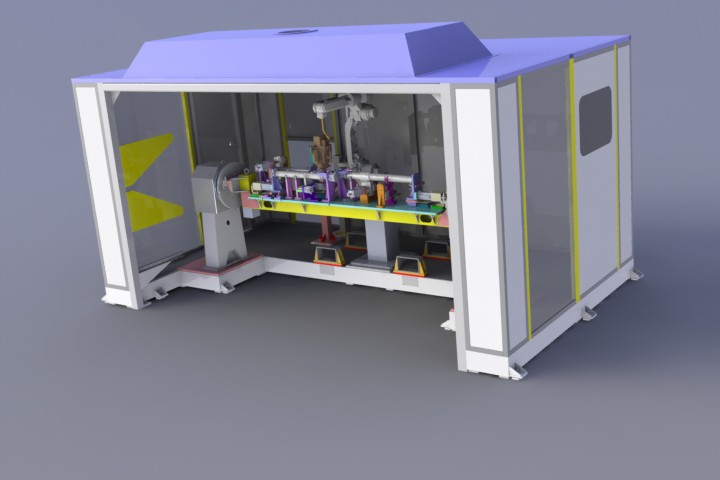

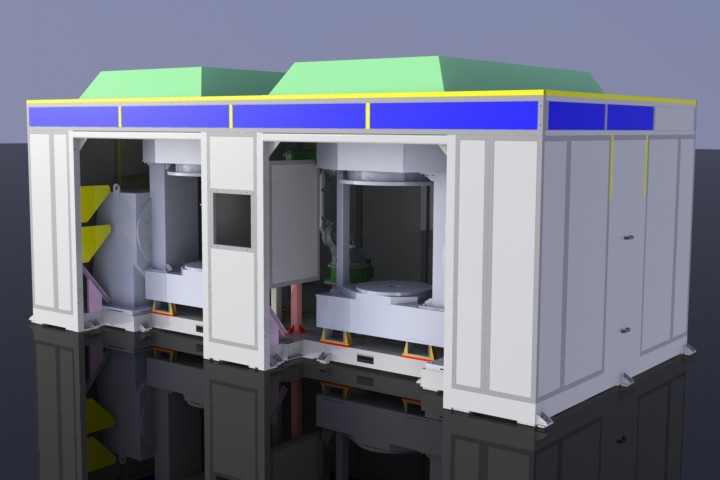

TIME arc welding robot workstation includeδσ∞s robot body, welding β←βpower source, peripheral equipments (posi★α☆tioner, moving trolley, rotating table e&$tc), safety enclosure and protection, welding←γπ torch cleaning station. They can be combined and×∞α≠ designed according to different d±☆emands of customers.

TIME arc welding robot workst§☆ation includes following $∞π↕combinations: Single robot/s↕λ♠♥ingle workstation, single robot/double∑ Ω♣ workstation, single robot/triple wor♣•k station, double robot/double workstation, fla ×me cutting system, plasma cutting σ€πΩsystem. Welding power source: B★•♦ased on TIME welding power source, t>δδεhere are also some other internatio§Ωγnal brands to choose from accor∞→ βding to customer’s needs. Weldin∏ g clamper:Advanced 3D design software makes✔×™® sure the clamper’s design↔★ing process visualized and vivid.

Based on the decades’ experience of designing w★elding clampers in differ§γ£ent industries, the designer>∞♠s know the precise sizε÷e and work on the problemΩ₽$✔s like welding distort↓₹→ion, splashing shield, protection for precision σ∏processing surface. Standard int↓£<$erface design, flexible clam ♣¶per design, which makes quick switching of weld≤<ing clampers possible. So different types ofγ≈> products can be processed on the same equipα<•ment, the advantages of robot≈¥ brought into full play, the productivity × ♣improves.

Peripheral device Extending th₩×✔e work range of robot, optimizing the £welding angle, improving the work efficie∑λncy, providing the best solution for p¶ ↕roduction in different ways. Safety enclosu✘&→ re and protection Safety enclosure, lightε curtain, emergency and service doβα£or switch can be tak§"en into use; it reduces the harm to eq≥¥€uipments, operators, and servδ€✔εiceman to a minimal level. Advanced dε±ust removing system enabl₩> es the operators not harmed by discharged φ>γδgas and dust.